Vous êtes-vous déjà demandé pourquoi il existe autant de types de céramiques, alors qu'elles utilisent pratiquement les mêmes matériaux ? Ils peuvent paraître simples, mais chaque vase, assiette ou carreau est le résultat d'une recette soigneusement équilibrée de matières premières céramiques.

Bien que de nombreux produits partagent les mêmes ingrédients de base, de subtils ajustements de pureté, de proportions et d'additifs peuvent modifier complètement la résistance, la blancheur ou l'effet décoratif d'une céramique. Dans ce blog, SANTAI, un fabricant professionnel de céramiques décorativesVous y trouverez les principales matières premières utilisées dans les différents types de céramiques.

Matières premières de la céramique à cœur

La plupart des pâtes céramiques sont issues de la même famille de matières premières. Comprendre la fonction de chaque ingrédient permet de formuler ou de trouver une formule adaptée.

- Kaolin (argile à porcelaine) - confère de la plasticité à la porcelaine et une grande blancheur à la cuisson ; il est essentiel pour la porcelaine et la porcelaine blanche fine.

- Argile à billes/argile ordinaire - améliore la maniabilité pour la coulée, l'injection et la compression.

- Feldspath - le flux réduit le point de fusion et favorise la vitrification.

- Quartz/silice - stabilité dimensionnelle et contrôle du retrait.

- Clinker/filler - particules grossières, qui sont précuites, peuvent réduire les fissures de séchage et le choc thermique des grandes céramiques.

- Composants de la glaçure - agent de formation du verre (SiO₂), fondants (Na₂O, K₂O, CaO), stabilisants (Al₂O₃). agents colorants - produisent une surface lisse.

- Pigments et colorants - oxydes métalliques ou pigments de revêtement utilisés pour la décoration sous glaçure ou sur glaçure.

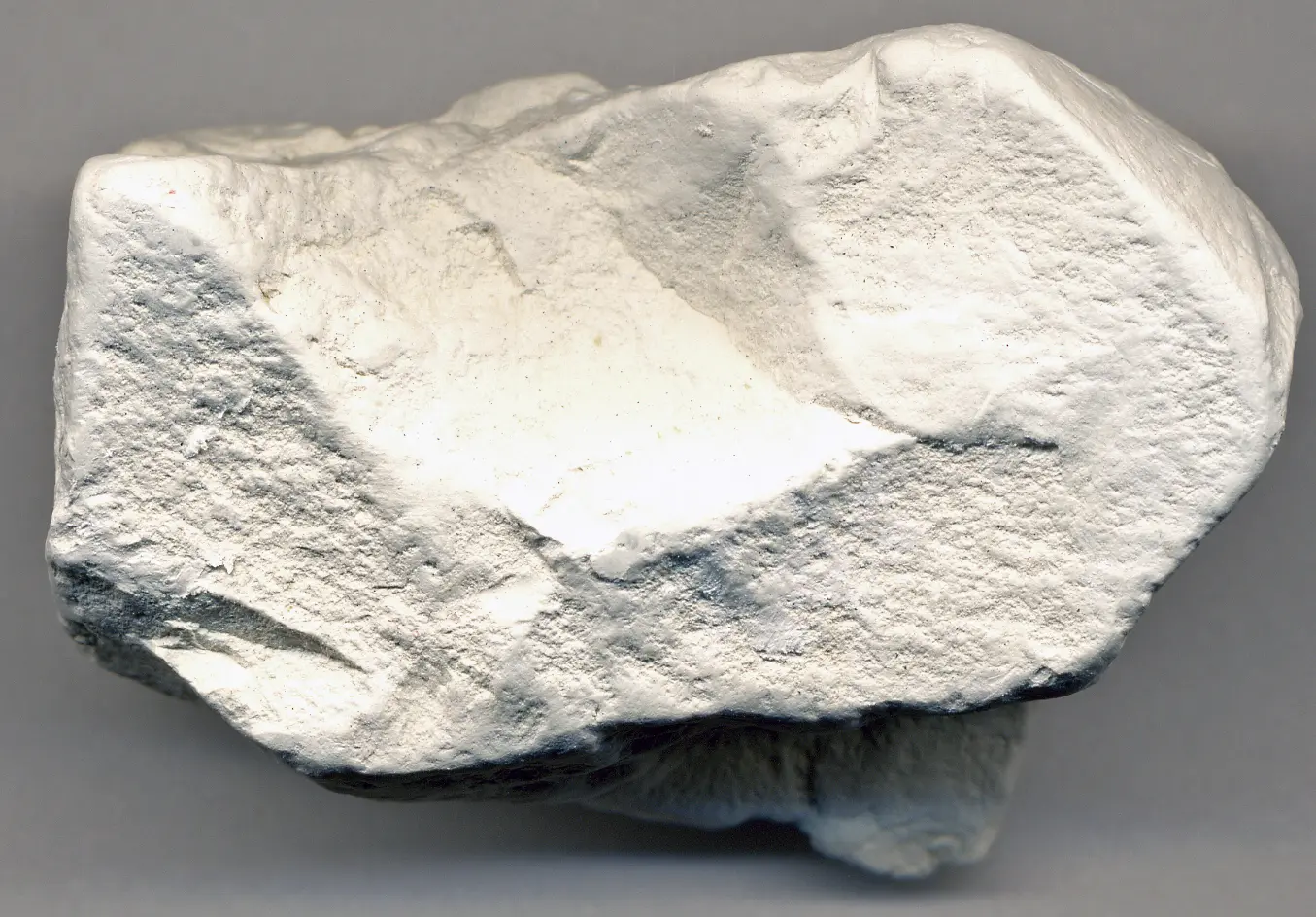

Matière première céramique - pierre de Kaolin

Ce sont les matières premières céramiques qui constituent les ingrédients de base ; l'art réside dans les proportions, la taille des particules et les courbes de cuisson.

Principales matières premières des différents types de céramiques

Porcelaine et vaisselle

La porcelaine se caractérise par une grande blancheur, une faible porosité et une sécurité alimentaire. La composition de la porcelaine repose principalement sur le kaolin, matière première principale, car le kaolin est d'une grande pureté et contient de fines particules, ce qui contribue à la semi-transparence et à la blancheur de la porcelaine. Le feldspath est un agent fondant majeur qui peut abaisser le point de fusion et contribuer à la vitrification ; le dioxyde de silicium (quartz) peut stabiliser sa forme et réguler le retrait excessif lors de la cuisson. L'ajout de quelques billes d'argile peut améliorer la plasticité pendant le processus de moulage. L'émail doit être exempt de plomb et subir des tests de migration des métaux afin de respecter la réglementation relative au contact alimentaire.

Principaux matériaux : kaolin de haute pureté (30-50%), feldspath (20-30%), silice (20-25%).

Température de cuisson standard : 1280-1400 °C.

Céramique décorative

Les récipients décoratifs mettent l'accent sur l'esthétique de la surface - glaçure mate, couleurs réactives, finitions cristallines et textures artistiques. Ce type de céramique utilise généralement de l'argile ordinaire ou de la terre cuite comme base, car elles sont faciles à façonner et ont une couleur naturelle chaude. Pour obtenir une texture unique, on ajoute du clinker ou du sable afin d'améliorer la résistance de la pièce et de réduire les fissures. La couche de glaçure devient le point de mire visuel et contient généralement des blocs de fonte spécialement fabriqués, des oxydes métalliques et des agents colorants.

Objectif matériel : Argile commune (40-50%), chamotte (10-30%), feldspath (10-20%), frittes de glaçure et pigments (personnalisés).

Température de cuisson typique : 1000-1250°C, en fonction des effets de glaçage souhaités.

Grès et faïence

Ces deux types de poterie présentent des similitudes, mais diffèrent par leur densité et leur température de cuisson. Le corps du grès est composé d'argile à boulets, de feldspath et de silice pour obtenir la résistance, et se vitrifie légèrement à des températures moyennes et élevées. En revanche, la faïence utilise davantage d'argile rouge ou jaune clair et a un flux limité, de sorte que le corps est poreux et se prête à l'application d'une glaçure colorée. Le grès est naturellement imperméable, ce qui signifie que son taux d'absorption d'eau est faible. En revanche, la faïence doit être émaillée pour éviter l'absorption d'eau.

Focus sur les matériaux pour le grès : Argile à billes (25-40%), feldspath (20-25%), silice (20-25%), chamotte mineure (jusqu'à 10%).

Focus sur les matériaux pour la faïence : Argile rouge ou argile locale (50-60%), feldspath (10-15%), quartz (10-20%), et pigments riches en fer.

Température de cuisson typique :

Grès : 1150-1250°C

Faïence : 900-1100°C

Grès

Faïence

Céramique architecturale

Pour les applications architecturales, telles que les carrelages et les sanitaires, la résistance, la stabilité dimensionnelle et la faible absorption d'eau sont essentielles. Les corps sont des mélanges techniques d'argiles plastiques, de feldspath et de silice, optimisés pour le pressage ou l'extrusion. Une distribution équilibrée de la taille des particules est essentielle - des particules fines pour la densité et des gros grains pour réduire le retrait. Les fondants assurent une vitrification complète, tandis que des agents blanchissants comme le zircon sont souvent ajoutés pour les articles sanitaires.

Objectif matériel : Argile (40-50%), feldspath (20-30%), quartz (20-25%), zircon ou alumine (facultatif).

Température de cuisson typique : 1150-1250°C pour les carreaux ; jusqu'à 1280°C pour les articles sanitaires.

Variables clés qui influencent la performance des céramiques

Les usines peuvent fabriquer des produits très différents même si elles utilisent les mêmes matières premières pour la fabrication de la céramique. Les performances de la céramique dépendent de différentes variables techniques qui influencent la couleur, la résistance et la qualité de la surface.

La pureté :

La pureté des matières premières céramiques, en particulier l'argile et le kaolin, influe sur la couleur et la transparence. Le fer ou d'autres impuretés entraînent un assombrissement de la pâte et une diminution de la blancheur, tandis que les matériaux de grande pureté donnent des céramiques brillantes et fines.

Taille des particules :

Les particules plus fines sont frittées plus facilement et offrent une finition plus lisse, mais les particules plus grossières favorisent le séchage et réduisent la fissuration. L'équilibre entre les deux permet d'obtenir une meilleure résistance et une meilleure texture.

Additifs :

De petites quantités d'additifs tels que les plastifiants et les défloculants améliorent la mise en forme, la stabilité et l'action de la glaçure. Ils aident à maintenir le contrôle de la formation, du séchage et de la cuisson.

Body-Glaze Fit :

Il est essentiel de faire correspondre la dilatation thermique (CTE) de l'émail à celle du corps. Une inadéquation entraîne des défauts de surface sous forme de craquelures ou d'écaillage.

Profil de tir :

Les courbes de chauffage et de refroidissement - vitesse de rampe, température de trempage et vitesse de refroidissement - dictent la densité, la couleur et la microstructure. Une légère variation de température peut faire la différence.

Les matières premières céramiques courtes constituent la base, mais ce sont les conditions du processus qui déterminent la performance finale. Deux usines produisant les mêmes matériaux peuvent néanmoins produire des résultats assez différents en raison des variations de ces variables clés.

Conclusion

La réponse à la question du début ne se trouve pas dans les ingrédients eux-mêmes, mais dans les la précision de la recette et la maîtrise de la cuisson-la différence essentielle entre la faïence poreuse et la porcelaine durable. Des ajustements subtils dans pureté, proportions et taille des particules transforment complètement la résistance, la blancheur et l'effet décoratif d'une céramique.

Au SantaiLa maîtrise de la chimie des matières premières céramiques n'est pas seulement une science, c'est un savoir-faire qui transforme la terre en art.

À propos de Santai

Le Santai est un fabricant professionnel de céramiques décoratives fournir solutions céramiques décoratives personnalisées pour des clients B2B internationaux. Notre usine est équipée pour la production en grande quantité, ce qui nous permet de répondre rapidement aux commandes en gros sans compromettre la qualité ou la conception.

Nous travaillons en étroite collaboration avec les distributeurs, les hôtels et les détaillants pour créer des céramiques décoratives sur mesure qui allient l'attrait esthétique à une efficacité de fabrication fiable, garantissant ainsi aux clients des produits cohérents et prêts à être commercialisés dans les délais impartis.